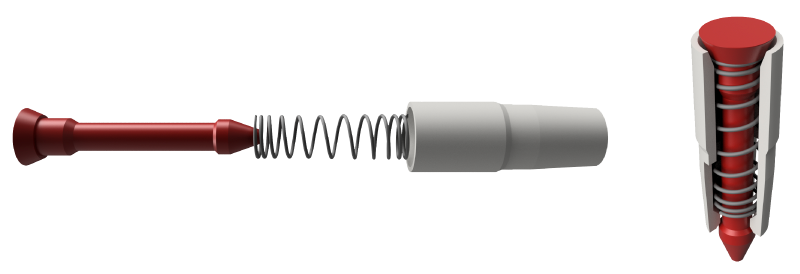

GSV spring vents for tire curing are the only patented demountable solution that is available on the market.

Glebus Spring vent technology which was started to be commercialized in 2009-2010 have created mountainous waves in the rubber compound and curing world. Their unique demountable, two-piece demountable design provides a lot of flexibility that older spring vents type. Glebus Alloys has created a completely new technology and support system based on this patented product.

We are offering our customers complete service and guidance through all steps in spring vents implementation into your production. Glebus Alloys is also capable to provide you with mold reworks from microvents to spring vents.

In Stock Parts for Reduced Lead Time

In Stock Parts for Reduced Lead TimeVent Outside Diameter

Ø2.0mm

Ø2.5mm

Ø3.0 mm

Ø3.2 mm

Ø3.5 mm

In addition to lowering manufacturing costs, GSV has proven to improve tire uniformity,

performance and quality vs. conventional venting.

G-Metal self-lubricating plain bearings and bushings with a sintered sliding layer are especially suitable for continuous operations in a demanding environment. Sintering technology allows for the construction and manufacturing of a wide range of complex shapes with consistent self-lubricating properties throughout the whole lifecycle of the critical moving parts. G-Metal based materials provide reliable and high-performance no-grease solutions.

Our G-Metal products for Tire manufacturers come with 5 year warranty

Glebus Alloys produces G-Metal, a unique, self lubricating material for wear surfaces. Our designs can be customized to fit your needs.

Shapes

The material can be formed into many shapes and sizes including wear plates, rolled bushings, cylindrical bearings, spherical bearings, split bearings, sleeves, liners, guides and other customizable shapes. A patented conical wear plate is also available for certain industry applications. Unlike graphite plugged bronze, the material keeps its self lubricating properties during the entire wear life cycle of whatever part it is formed into.

Alloys

A variety of alloys can be formed with G-Metal material. Bronze, nickel, iron, iron/nickel and lead can be produced with the lubricants graphite or graphite and molybdenum.

Bimetallic Option

To increase strength and reliability, G-Metal can be laminated to a steel or stainless steel backing. Manufactured by a continuous hot rolling sintering technology, the reliability and service life is greatly increased compared to conventional wear material. This bimetallic form of G-Metal is available in many shapes and sizes. While wear plates are the most common, the material can also be used for bushings, bearings and other applications.

We are able to offer and ensure the installation of our product. From complete mold rework to spring vents to basic mold vent maintenance.

Team of dedicated engineers with background in tire industry are able to help you on site with any challenges you might be facing

Every tire makers uses different compounds and curing parameters. That means adjusting of our product to meet each customers specific demands. Turn key solutions are available.

HEAD OFFICE

GLEBUS ALLOYS EUROPE, s.r.o.

Náměstí Míru 341/15

120 00 Vinohrady, Prague 2

Czech Republic

Tel. EU +420 491 421 211

Tel. US +1 (330) 867-9999

sales@glebusalloys.com

info@glebusalloys.cz

Back to glebusalloys.com